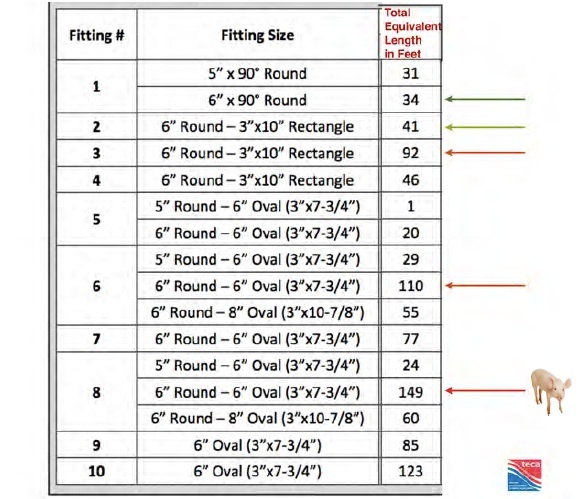

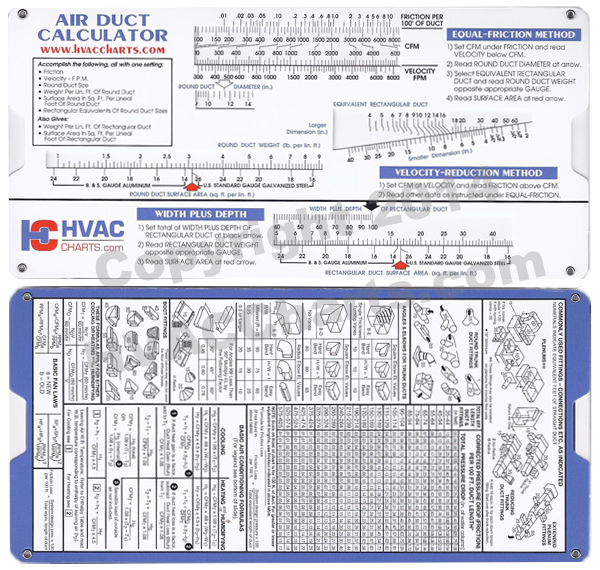

When you add up the effective lengths of all the fittings and then add that number to the length of the straight sections in the most restrictive runs in the return and supply ducts you find the total effective length tel.

Hvac duct fittings equivalent length chart.

The strength of the equivalent length method is that it is very simple to calculate.

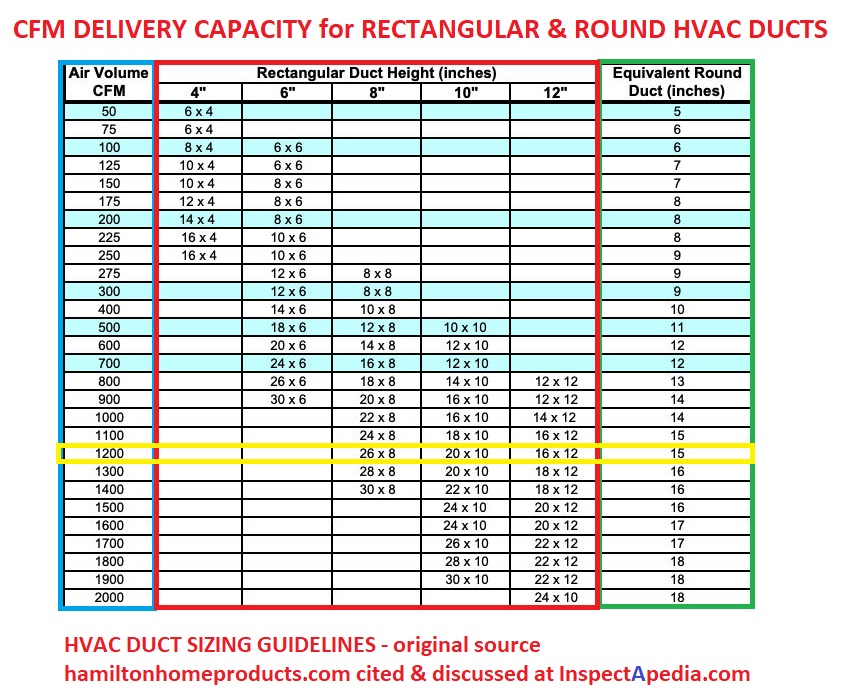

Use the friction chart at 1000 cfm in 9 4 inch diameter to friction loss is 0 5 in water 100 ft.

A common duct pressure of 0 25 inches water column is equal to 0 25 divided by 27 7 in wc psi 0 009.

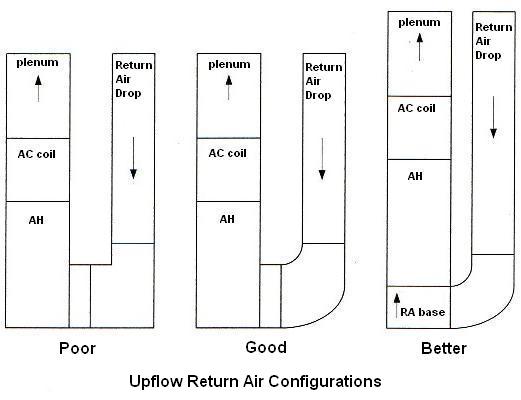

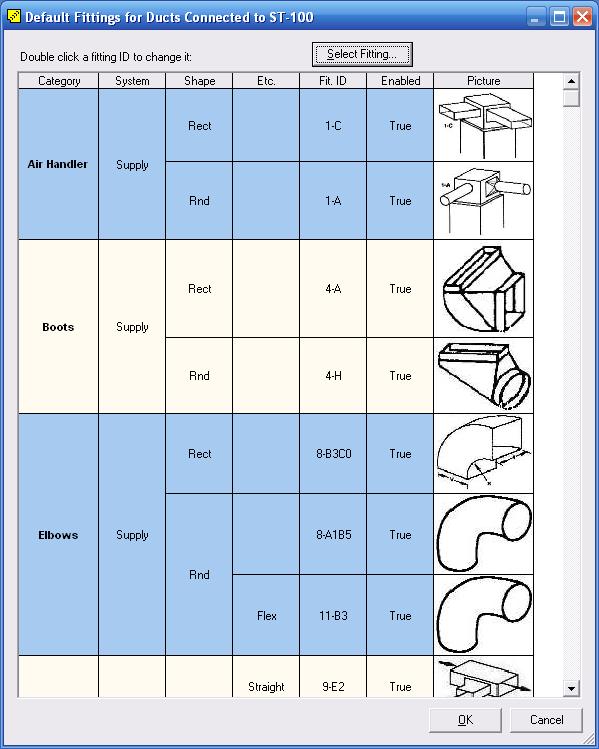

Energy vanguard this duct design shows the layout of a duct system including the fittings and duct sizes.

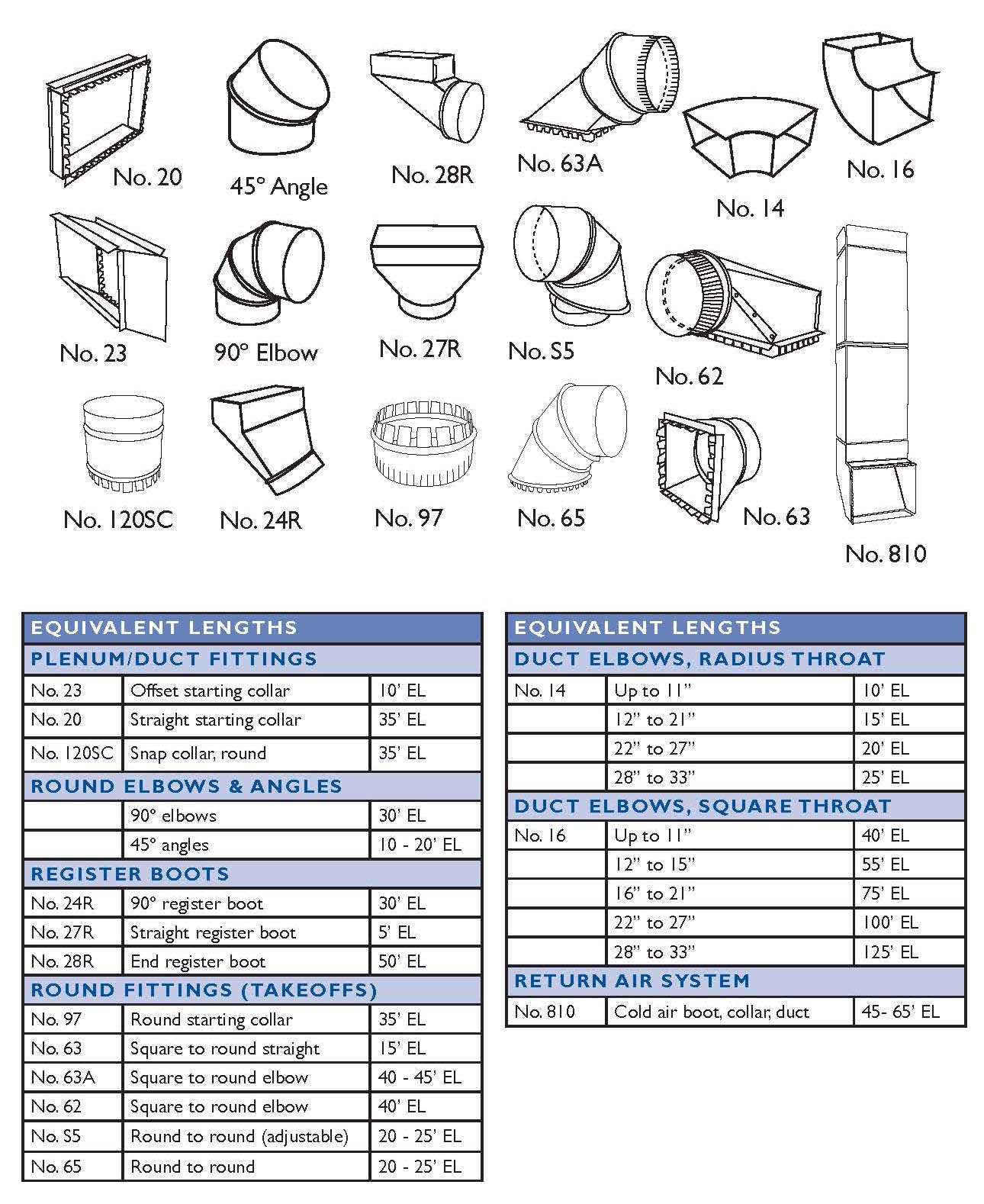

Each fitting has an effective length that equates its pressure drop to an equivalent amount of straight duct.

Ordinary heating ventilating and air conditioning duct systems read air pressures at 0 4 psi or less often much less.

Equivalent lengths become important to the hvac system designer who is looking to ensure proper airflow distribution with the equal friction method of duct sizing.

This article details the calculation of pressure losses through pipe fittings and some minor equipment using the equivalent length method.

The sum of all equivalent lengths of fittings used and the measured distances of all pipe and duct from room terminal to the air handler should be calculated for each.

The weakness of the equivalent length method is that.

One method of duct design relies on calculating the total effective length which is the sum of all the lengths of the straight sections of duct and the equivalent lengths of the fittings.

From table a 3 the equivalent round size is 9 4 inches.

Fittings such as elbows tees and valves represent a significant component of the pressure loss in most pipe systems.